Click this messge to hide it.

REPACKAGED PRODUCT: This repackaged metal product offers an opportunity to save money. Similar to an ex demo or seconds quality, all major components should be usable with no significant shortages. The packaging may not be in new condition and there may be signs of use, scratches and other imperfections. Any creased edges are normally straightened easily or obscured during assembly. If the product or packaging is not as new we offer the product for sale as “repackaged”. Savings are calculated against the retail price of a new product as of 26th January 2026.

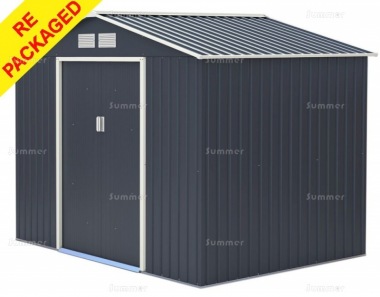

- Hot dip galvanized steel framing

- Hot dip galvanized steel cladding panels with a tough epoxy resin coating inside and out

- Attractive grey colour to external cladding

- Contrasting colour to gable fascias and door frame trims

- Pale colour to all internal cladding

- Double sliding doors in the 9'1" wide front wall

- Pair of door handles pre-drilled with 10mm diameter holes to suit most padlocks

- Vertical, horizontal and diagonal door framing

- Cladding sheets are corrugated and ribbed for extra strength

- Corner cladding sheets are folded ninety degrees and overlapped to provide a strong and waterproof corner joint

- 100mm x 30mm intermediate roof purlins

- 100mm x 60mm main ridge beam

- 125mm x 30mm door threshold and ramp

- 110mm x30mm and 55mm x 30mm foundation rails

- 120mm wide external ridge cover

- 4 louvred ventilators are fitted to the front and rear gables for improved ventilation

- Eaves height approximately 5'6" (1676mm)

- Ridge height approximately 6'8" (2020mm)

- Door height approximately 5'4" (1616mm)

- External roof size 9'1" wide x 6'3" deep (2770mm x 1910mm)

- External cladding size approximately 8'9" wide x 5'11" deep (2670mm x 1810mm)

- Overall weight 68kg excluding floor - heavier than similar metal sheds supplied by others

- This shed is easy to deliver if access is restricted - all sections are designed to pass through a normal single door

GALVANIZED STEEL CLADDING: These great value buildings are made with galvanized steel throughout. All framing and cladding is hot dip galvanized steel. This is a process by which steel is coated with zinc to protect it from corrosion. The cladding is subsequently coated with epoxy resin, partly to protect the zinc coating itself and partly to add colour. The factory finish is described as primer although a top coat is not normally needed. The combination of a zinc coating with epoxy resin provides durable protection even if the surface is scratched.

STRONG FRAMING: In common with all other steel buildings, including even the largest sports stadia, retail superstores and warehouses, steel cladding sheets are surprisingly thin. The strength of steel buildings is provided by the frame, although the corrugations of the cladding sheets do provide a degree of extra strength. These metal sheds feature strong galvanized steel framing members and the completed frame is rigid.

HEAVY PACKS: As a rough and ready rule, the heavier a metal shed is the stronger it is. Our sheds are heavier than most similar metal sheds which is why we publish the weight. The packs are very heavy but surprisingly compact, especially the cladding sheets which are packed tightly together.

SIZES - DEPTH AND WIDTH: Sizes are sometimes rounded to the nearest nominal size for ease of reading but the correct external sizes are listed alongside the price. The sizes listed alongside the prices are the external roof sizes. The external wall sizes may be smaller. The first dimension listed is the width and the second dimension is the depth. The width refers to the angled gable walls at the front and rear including the door wall. The depth refers to the side walls. All sizes are approximate.