Click this messge to hide it.

- Free same day installation

- Free mortar fillet to the internal walls

- 10 year structural guarantee

- External brick or stone effect finish with a choice of colours

- Overlapping cladding panels

- Complimentary coloured composite corner caps

- External pebbledash finish with Canterbury Spar chippings for all walls not featuring brick or stone effect cladding

- Large full height panels with fewer joins and neater internal lines

- Attractive smooth vibrated internal finish

- Strong interlocking rebated concrete panels

- Galvanized bolts

- Apex roof with 12.5 degrees pitch

- Welded steel roof trusses with red oxide finish

- Substantial pressure treated timber roof purlins (lifetime preservative treatment)

- Brown cement fibre roof sheets

- Foam filler to eaves

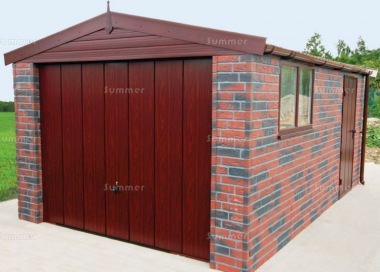

- Dark woodgrain foil laminate finish included to all windows, doors and fascias - an attractive, tough, durable and permanent finish

- Low maintenance dark woodgrain finish PVCu fascias

- Dark woodgrain finish 2 pane non opening double glazed PVCu window 4' wide x 2'6" high (1220mm x 750mm)

- Brown square line PVCu guttering with downpipes

- Low maintenance dark woodgrain finish PVCu personnel door 3' wide (915mm)

- Dark woodgrain fully retractable galvanized steel up and over door with attractive vertically ribbed design

- Brown PVCu clad door frame

- Up and over door height 6'6" (1980mm)

- Minimum up and over door clearance height 6'2" (1880mm)

- Garages 8' wide feature a central 7' (2130mm) wide up and over door

- Garages 9' wide feature a central 8' (2440mm) wide up and over door

- Garages 10', 12' or 14' wide feature an 8' (2440mm) wide up and over door which can be central or offset to one side

- Garages with offset doors include a front wall section which can be located to either side of the door

- Standard eaves height 6'6" (1980mm)

- External ridge height approximately 7'9" or 2360mm (8' wide garages)

- External ridge height approximately 7'10" or 2390mm (9' wide garages)

- External ridge height approximately 8'0" or 2440mm (10' wide garages)

- External ridge height approximately 8'2" or 2500mm (12' wide garages)

- External ridge height approximately 8'5" or 2560mm (14' wide garages)

FREE SAME DAY INSTALLATION - THE BENEFITS: Our free in house installation service is not just convenient, it is also your assurance of a better quality sectional garage. This is because any building which includes free installation is invariably better made using quality components. Over time regular feedback from fitters ensures that design faults and weaknesses have been rectified. Same day installation is convenient for you and cost effective because it saves travelling costs. The fitters will deliver your sectional garage and then install it, all at the same time. Others send sub-contract fitters separately, often from far away and often a week or two after the delivery. Waiting for the fitter can be very frustrating. Sub-contract fitting is also much more expensive because of the travelling costs. The fitting service does not include base preparation. A flat and level base is required, which should be made using concrete. In many areas we offer a base laying service as an option.

CONCRETE GARAGES - THE BENEFITS: Many of our timber garages and log cabin garages are solid, well made and likely to last a long time with very little maintenance. However, nothing can match the solidity and durability of a sectional concrete garage. If you choose PVCu windows and gables your concrete garage will be almost completely maintenance free. Sectional concrete garages rank highly as one of the most desirable home improvements.

BRICK OR STONE FINISH: The heavy duty concrete panels are approximately 65mm thick and steel reinforced. The panels are finished outside with a sensational brick or stone finish which is attractive, durable and maintenance free. The cladding is attached to the concrete walls using a concealed fixing system. The cladding panels neatly interlock, giving a continuous brick finish with no piers and barely visible joins. The corners are neatly finished with a composite capping. This cost effective cladding system reproduces the appearance of a traditional brick building extremely well. The finish is very tough and impervious to water and it will look good for years to come. You can choose to clad two, three or all four sides of your building. Any wall which isn't brick or stone clad features colourful Canterbury Spar chippings. The inside features full height panels with a smooth vibrated finish to ensure a neat appearance. The smooth internal finish is attractive in itself but it is also easy to paint which provides a stunning internal finish. The cladding specialists will arrive on site to apply the brick cladding about a week after installation but you can use your building prior to their arrival. The cladders will need to be able to get all the way around the building to fit the cladding panels. The cladding is available in a choice of colours and finishes.

FULLY RETRACTABLE UP AND OVER DOORS: Our up and over doors are fully retractable, which is neater and stronger than the canopy doors supplied with most garages. Although the door projects during opening there is no projection once the door is fully open. The performance is smoother and more reliable than a canopy door with no wire cables to maintain. Instead the door features heavy duty springs and the wheels are firmly retained in rigid metal channels. An anti-fall safeguard ensures that even if a spring fails the door is held in position. The design ensures no steel to steel contact and a spring buffer stop ensures that the door comes to a safe stop when fully open. An internal handle and lock are included. The four point locking system (fitted as standard to garage doors up to 9' wide) ensures security.

WELDED STEEL ROOF TRUSSES: All garages feature a substantial roof structure with one piece welded steel trusses which span from side to side. The trusses are bolted to the concrete panels and spaced up to 6' apart. All trusses have a red oxide factory primed finish.

PRESSURE TREATED TIMBER: Pressure treatment is a lifetime preservative treatment. The preservative is forced deep into the timber under pressure in a vacuum and penetrates below the surface. All other treatments apply a coat of stain to the surface of the timber only. With pressure impregnated timber, the chemicals are permanently bonded to the cell structure of the wood at a molecular level. Tanalith E is a widely used water based version so pressure treated wood is often described as tanalised. Pressure treated wood is almost colourless except for a slight green tint caused by the copper content in the preservative. No further preservative treatment is ever needed. However, if you want a coloured finish you can paint over pressure treated or tanalised wood with a suitable wood preservative in any colour.

CEMENT FIBRE ROOF SHEETS: These robust cement fibre roof sheets offer excellent noise and thermal insulation. They are rust, rot and corrosion-free, with superb drainage properties. The 5" profile sheets are 20% thicker than many rivals, making it highly impact resistant. A strong ridge cap is also included.

WOODGRAIN FINISH: Our woodgrain finishes are achieved using materials with a woodgrain laminate foil applied to the external surface. The foil is extremely hardwearing and lasts almost indefinitely with little or no maintenance. Occasional cleaning with soapy water is all you need to restore the original appearance. The foil has a detailed and authentic woodgrain appearance and it can be applied to PVCu windows, PVCu fascias and PVCu or steel doors. Our woodgrain concrete buildings look stunning when sited at a property with similar windows and fascias. We offer a choice of Light Woodgrain and Dark Woodgrain to suit the majority of properties with woodgrain PVCu windows or stained timber windows.

INTERNAL MORTAR FILLET: The price includes laying a mortar fillet on the inside of your building between the concrete panels and the base to prevent water ingress under the walls. This important finishing touch is not always included with other concrete buildings.

INTERNAL SIZES AND BASE SIZES: Concrete garages require a substantial concrete base which should be slightly larger than the garage. The ideal size is 3" or 75mm bigger than the garage on all sides. To calculate the correct base size for any garage just add 6" or 150mm to the external garage width and 6" or 150mm to the external garage length. Sizes are sometimes rounded to the nearest nominal size for ease of reading but the correct external wall sizes are listed near the prices at the top of the page. The internal sizes are approximately 5" or 125mm smaller than the external sizes. All sizes are approximate.

SIZES - LENGTH AND WIDTH: Sizes are sometimes rounded to the nearest nominal size for ease of reading but the correct external wall sizes are listed alongside the price. The first dimension listed is the width and the second dimension is the length. The width refers to the angled gable walls at the front and rear including the door wall. The length refers to the side walls. The sizes listed are the external wall sizes. These sizes do not include the roof overhang. All sizes are approximate.