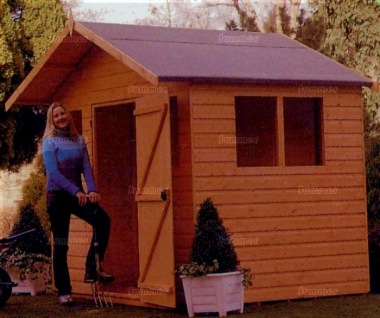

- The walls of these sheds are interchangeable and the side windows can be located to either side. This can be decided on site and does not need to be specified when the shed is ordered.

- Shiplap wall cladding - tongued and grooved boards 120mm x 12mm finished size after machining

- Loglap wall cladding - tongued and grooved boards 95mm x 15mm finished size after machining

- Opening windows

- Two tier timber workbenches, made to the same lengths as the internal walls to ensure a neat fit.

- Additional security features

- Recycled plastic base kits

- Portable indoor gas heaters - no need for an electricity supply or trailing leads

- A selection of microporous wood preservatives in a wide choice of colours

RECYCLED PLASTIC BASE KITS: Our durable eco-grid and eco-paving base kits are a practical and affordable alternative to slabs or concrete. Lightweight and easy to install within a few minutes, these recycled polypropylene pavers simply click together with no fixings needed. The interlocking design helps to spread weight and ensures greater rigidity. Weed membranes are not needed below a timber floor. The self draining design prolongs the life of a timber floor. Unlike paving or concrete our plastic bases are fully relocatable. The base is normally at least 2" or 50mm larger than your building. Where space permits the base is normally laid full size but if required in a tight location our plastic pavers can be cut. Fast delivery within 3-5 days ensures that you can start work quickly.

ECO-GRID BASE KITS: Eco-grids are recommended if the sub-base is soil, sand or pea shingle but not on hard surfaces such as concrete, because the underside is not flat. Integral pegs on the underside help to level the base grids more easily in soil or sand or shingle. Our eco-grid plastic bases can support up to 200 tonnes per square metre. We offer exactly the same eco-grids as driveways and carparks. Gravel or shingle infill is not required below a timber floor. Whatever you store in your building, our eco-grids will support the weight easily. Each eco-grid is 472mm x 472mm and 40mm thick with an immensely strong 60x60mm hexagonal cell structure. Extensive preparation is not normally required - just level the soil and lay the pavers directly on soil or on a thin layer of sand or pea shingle. Any exposed edges around the base can be left unfilled or filled with gravel or shingle.

ECO-PAVING BASE KITS: Eco-paving is recommended if the sub-base is a hard surface such as concrete or paving slabs, because the pavers feature a flat and level underside. Our eco-paving is less brittle than concrete paving slabs, with a strong supporting structure. The surface looks and feels similar to pressed concrete slabs, with a slightly textured finish. Each eco-paver is 385mm x 385mm and 40mm thick. The pavers are quickly and easily easily laid over an existing hard surface.

MICROPOROUS PRESERVATIVE - DELIVERED TO YOUR DOOR: Our quality microporous preservatives are impervious to water but not to water vapour. This allows the wood to breathe. You can order up to 3 separate colours if required. At least two coats are normally required with a further coat at periodic intervals.

Our 3 star preservative is practical and affordable with a choice of 4 colours. It covers around 10 square metres per litre and normally lasts 1-2 years before a further coat is required.

Our 4 star preservative is a high quality preservative which covers around 9 square metres per litre and normally lasts 2-5 years before a further coat is required. It is available with a choice of 12 colours.

Our 5 star preservative is a deluxe high build preservative which can be used to achieve a stunning finish. Each extra coat increases the colour and sheen. It covers around 8 square metres per litre and normally lasts 2-5 years before a further coat is required. It is available with a choice of 12 colours.

Based on average coverage five litres of our 4 star preservative is enough for two coats on an 8'x10' shed or an 8'x8' log cabin. Ten litres is enough for three coats on a 10'x16' shed or a 12'x10' log cabin. Coverage varies according to the smoothness of the surface and the porosity of the timber. We recommend that you order more than you need to be sure that you have easily enough. All of these preservatives are safe for use with children and pets. These microporous preservatives are only available when you purchase a Summer garden building or if you purchased a Summer building in the past. Prices include free mainland delivery to England, Wales and southern Scotland. Colours are only as accurate as reproductive techniques allow.

WATERPROOF COLOUR SEAL - DELIVERED TO YOUR DOOR: This advanced water-based microprous timber treatment uses the latest high-tech nanotechnology to create a long-lasting waterproof wood coating that is environmentally friendly. It is suitable for use on all softwood and hardwood products and is especially recommended for use on pressure treated timber, including sheds, summerhouses, gazebos, fencing and garden furniture. This timber treatment will colour, protect and enhance your exterior wood. It contains a mould inhibitor to protect the coating and can be used on all outside and inside timber. It gives a traditional matt wood stain finish in a range of natural colours. It can easily be applied by sprayer, brush or roller. It is recommended that the second coat is applied as soon as the first coat is touch dry. We advise for ultimate performance the timber has a wood preservative pre-treatment. For the first treatment, two coats are recommended and will give a traditional wood stain finish that is long lasting. A further coat is recommended every 2-5 years. One litre covers approximately 10-12 square metres. Coverage varies according to the smoothness of the surface and the porosity of the timber. On average five litres covers a 12x8 shed with two coats and ten litres covers a 10x20 with three coats. It is recommended that 2 coats be applied. We recommend that you order more than you need to be sure that you have easily enough. The appearance of colours and shades may vary between different screens or devices. Prices include free mainland delivery to England, Wales and southern Scotland.

WATERPROOF CLEAR SEAL - DELIVERED TO YOUR DOOR: Our hardwearing clear seal is ideal as a clear varnish for bare timber or as a waterproof top coat for painted wood and pressure treated timber. It is also ideal as a waterproof floor varnish, especially the polyurethane clear seal. The smooth and shiny finished surface is waterproof and easy to clean. Available in a choice of acrylic or polyurethane, these colourless water based coatings are almost odourless and recommended for smooth planed timber only. One coat is normally required as a sealing top coat on painted or treated timber. A minimum of two coats are normally required on untreated wood. Up to three coats may be required for floors. An unsealed timber floor quickly shows muddy boot marks and other dirt. For best results a floor should be treated at the earliest opportunity while the timber is new and clean. On average five litres of our 5 star clear seal is enough for three coats on a 12'x12' floor, two coats on the walls of an 8'x8' log cabin or one coat on the walls of a 12'x16' log cabin. We recommend that you order more than you need to be sure that you have easily enough. The price includes free mainland delivery to England, Wales and southern Scotland.

ADDITIONAL LOCKS: Heavy duty bolts, brackets and locks are available to provide additional security for your most valuable items. A heavy duty anchor bracket with a cable and padlock can be securely wall or floor mounted into brickwork, concrete or timber. The security cable is long enough to secure several items such as bicycles or a lawnmower. Padlocks are available with a closed shackle for security or a combination lock for convenience. Heavy duty sliding combination bolts can be fitted to single or double doors. The recodable combination bolt is quick and easy to use, with no keys to lose and no time wasted looking for keys. A hasp and staple set or a pair of door brackets can also be fitted to single or double doors. Ideally two pairs of brackets or two hasp and staple locks will provide a secure fixing point at the top and bottom of the door for maximum security.

BURGLAR ALARM: This simple and effective battery operated burglar alarm kit is easy to install in any wooden garden building. The main panel features a digital keypad and a powerful built-in siren. Two pre-wired door contacts are also included complete with a length of cable which plugs into the main panel. A 9 volt PP3 alkaline battery is required, which is not supplied with the kit. The alarm is easy to set using the digital keypad. A delay allows plenty of time to enter or leave the building after setting the alarm. Once the alarm has been armed it will be triggered by opening the door or tampering with the wiring. When the alarm is activated the siren emits a powerful and unpleasant sound to deter intruders.

SOLAR POWERED LIGHTS: These ingenious and affordable solar powered lights are easy to install with no mains wiring and they cost nothing to run. During the day the externally mounted solar panel converts daylight into electricity and recharges the batteries. The solar panel is weatherproof and suitable for outside use. It is normally positioned high on the walls of your garden shed or on the roof. Our solar internal lights solve the problem of seeing inside your garden shed at night. Our solar security lights illuminate the approach to your garden shed at night and may also deter burglars. After dusk the passive infra red movement detector switches itself on when it detects movement. The more expensive solar lights are brighter and stay on for longer.